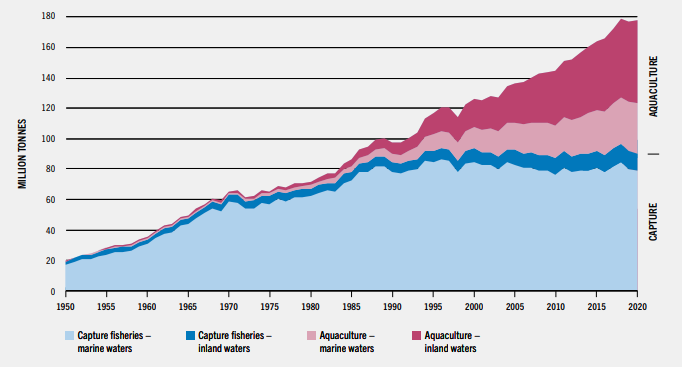

Aquaculture is a rapidly growing sector that contributes to food security, nutrition, livelihoods, and economic development. Global aquaculture production has been on the rise in recent years. In 2020, the total fisheries and aquaculture production reached 214 million tonnes, with aquaculture accounting for 57% of this total. Specifically, in 2020, global aquaculture production hit a record high of 122.6 million tonnes, valued at USD 281.5 billion. (1) Understanding the intricacies of constructing and maintaining aquaculture facilities is crucial for the sustainable and efficient production of a fish farm.

Aquaculture containment structures serve as the backbone of any successful aquaculture venture. Properly designed and maintained facilities ensure optimal growth conditions for aquatic species, minimize environmental impact and enhance overall productivity. However, poor maintenance can lead to costly setbacks, compromised water quality, and even ecological harm. In this blog, we will discuss the steps and best practices for choosing, planning, constructing, and maintaining aquaculture production units. We will also explore some of the future trends and innovations that could enhance the performance and sustainability of aquaculture systems.

Planning your fish production units

Before you start building your aquaculture production unit, you need to do some research and planning to ensure that your system is suitable for your site, your target species, and your objectives. The key factors that influence the design and construction of aquaculture production units are:

- Site selection: You need to choose a farm location that has adequate space, accessibility, security, and legal compliance. You also need to consider the potential environmental and social impacts of your aquaculture operation, such as water use, waste discharge, noise, odor, and conflicts with other users or stakeholders.

- Topography: The terrain and elevation of your site should be assessed, as they influence the flood risk, drainage, and erosion of your production units. You may also need to modify the landform or construct protective structures to prevent or minimize these risks.

- Hydrology: Ensure that your site has a reliable and sufficient water supply that is free from pollutants, parasites, and contaminants. You should also consider the water quality parameters, such as temperature, salinity, pH, dissolved oxygen, and nutrients, that affect the growth and health of your aquatic organisms.

- Soil conditions: Soil characteristics, such as texture, structure, permeability, fertility, and acidity should be evaluated. These influence the stability and productivity of your system. You may need to improve the integrity and fertility of the soil by using liners or filters to improve its suitability for aquaculture.

- Water supply: You need to determine the source, quantity, and quality of water that you will use for your system. You may need to install pumps, pipes, valves, filters, or other devices to transport and treat the water. Also, calculate the water budget and balance, taking into account the water input, output, and losses.

- Drainage: It is essential to design and construct an efficient and effective drainage system that allows you to control the water level, remove excess water, and dispose of wastewater. This may necessitate the use of gravity, pumps, siphons, or other methods to drain the water. The drainage system operation needs to comply with the regulations and standards for wastewater discharge and treatment.

- Aeration: To maintain optimal dissolved oxygen levels and prevent hypoxia or anoxia, the production units should be well aerated. You may need to use mechanical, electrical, or natural methods to aerate the water, such as paddle wheels, blowers, diffusers, fountains, or windmills.

After you have considered these factors, you can proceed to design your aquaculture production unit. Designing an aquaculture production unit involves selecting the appropriate type of system, tailoring it to the targeted species, and managing water quality. There are various types of aquaculture systems, such as ponds, cages, tanks, raceways, recirculating systems, integrated systems, and others.

Each targeted species has specific biological and ecological requirements, such as temperature, salinity, pH, dissolved oxygen, nutrients, and space. The selected system must provide the optimal conditions for the species to ensure their growth and good health. Water quality is critical for aquaculture success.

Construction phase

Fish ponds

a) Earthen pond

b) Concrete pond

c) Tarpaulin pond

A fish pond is an artificial structure designed to contain water for rearing fish. To succeed in fish farming, you need to have a suitable fish pond that meets the necessary requirements for growing fish. If you want to grow healthy fish in a pond, you need to pay attention to how you build and maintain it. A good pond should have these features:

- It should fill up and drain quickly so that unwanted plants and animals don’t get a chance to settle in before you stock your fish.

- It should keep a steady water level of about 1 meter throughout the production cycle so that your fish have enough space and oxygen to grow.

- It should allow you to monitor and manage the water quality during production.

- It should be safe from erosion and flooding so that your pond doesn’t get damaged or lose water.

- It should be easy and safe for you and your staff to access and perform your daily tasks, such as feeding, harvesting, and cleaning.

- It should be secure from predators and intruders so that your fish don’t get eaten or stolen.

Types of fish ponds

There are several types of fish ponds depending on the size, location, budget, and species of fish you want to raise. Some of the common types of fish ponds are:

- Earthen ponds: These are artificial ponds dug into the ground, usually in waterlogged or sloppy areas. They are the most natural and low-cost type of pond, but they may have problems with water retention, erosion, flooding, and water quality management.

- Concrete ponds: These are ponds made of concrete walls and floors, usually in urban or semi-urban areas. They are more durable and easy to manage, but they are also more expensive and require regular maintenance.

- Tarpaulin ponds: These ponds are made of waterproof fabric or plastic sheets, usually laid on an impoundment dug in into the ground, or supported by wooden or metal frames. They are portable and flexible, but they may not last long and may need frequent cleaning.

Steps of pond construction

These are the major steps in pond construction after determining the site and establishing the pond design according to proper pond standards;

Prepare the area for constructing the pond.

Clear vegetation, remove tree stumps, and debris around the pond area. Put aside the topsoil. Additionally, assess soil types across the proposed pond area to ensure suitable soil distribution.

Mark out the pond, its inlet, and drainage Construct the core trench

Use pegs to mark out the pond perimeter. Take more detailed measurements at the pegs to determine the levels and slope around the pond. Based on these measurements, ascertain and peg out the location of the inner and outer toes, the outlet, and if a harvest basin is desired, the location of the harvest basin. Additionally, take further measurements of levels from inner toes across to the drainage to ensure that the pond floor slopes appropriately towards the outlet, and determine the lowest point at the outlet.

Construct the core trench

This is an impermeable layer in between the pond walls or dyke meant to prevent seepage and sliding of the walls.

Construct the dyke

This is built up from the base, layer by layer by compacting above the core trench.

Construct the harvest basin (optional)

Install the outlet

Install the outlet before the inlet. When setting up a pond outlet, consider the following components; the stand-pipe, outlet pipe, bend, anti-seep collar, and anchor collar. Ideally, the pond inlet and outlet should be opposite each other to facilitate flushing. Outlets may be made of concrete or PVC pipes, but be aware that concrete tends to leak.

Install the inlet

To create an effective pond inlet system, excavate a trench with the desired slope at the shallow end for the inlet pipe. Choose a 2″ pipe for smaller ponds or those with limited water supply, and use a 4″ pipe for areas with adequate water. Ensure the inlet pipe is smaller than the outlet to prevent overflow. Position the inlet pipe at least 20 cm above the water surface to prevent fish escape. Avoid open earthen channels for commercial ponds, opting for pipes to ease screening and prevent erosion. Backfill and compact soil, and protect the dyke from erosion using methods like stone laying or concrete casting. Dress the pipe with a filter sock and screen the inlet to prevent fish from escaping or entering the pond. This approach ensures a secure and efficient pond inlet system.

Level, Smoothen and compact the pond bottom

Ensure the pond bottom is smooth and firm by eliminating potholes and leveling bumps, as these features provide shelter for predatory fish and pose a danger to pond workers. Compacting the pond bottom is crucial to prevent muddy conditions during production, which can lead to poor pond productivity and make seining difficult. Additionally, a smooth and firm bottom reduces the risk of fish getting trapped in mud when draining the pond. As you level and compact, pour water to ensure proper flow towards the outlet, contributing to a well-maintained and productive pond environment.

Strengthen the Dyke Tops and Free-Board Areas

Enhance the strength of the pond bank by compacting it once more. Cover the bank with topsoil extending down to the water line and lightly compact it. Plant grass over the topsoil, extend it down to the water level and ensure proper growth by watering it regularly. This process helps fortify the pond bank, promotes stability, and contributes to a well-maintained and aesthetically pleasing environment.

Maintaining a freeboard of less than 20 cm is risky during flooding, as fish, especially African catfish, can escape easily when the freeboard becomes wet. On the other hand, having a higher-than-recommended freeboard is discouraged due to unnecessary construction costs and the increased risk of attracting predators and burrowing animals like nutria and muskrats. Striking a balance in freeboard height is essential to prevent escapes and avoid unnecessary expenses.

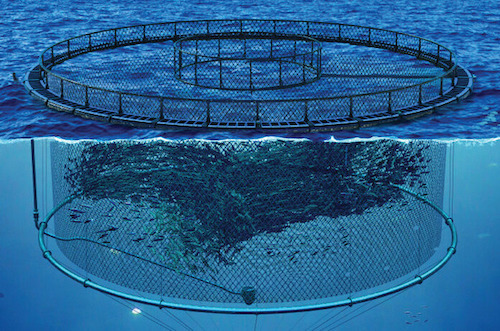

Fish cages

A fish cage is a container designed with mesh to serve the purpose of cultivating or temporarily containing aquatic animals within a water body. The mesh structure allows the clear flow of water into and out of the cage while preventing fish from escaping. Cages come in diverse shapes and sizes, offering versatility and adaptability for various applications in aquaculture.

a) Square cage

b) Circular cage

Types of fish cages

- Fixed cages consist of a net bag that is fixed to posts that are fixed into the bottom of the water body. They have a square or rectangular shape, and they cannot be very large. They are low-cost and simple to construct, but they can only be used in sheltered areas with slow currents and non-rocky but firm bottoms. A common example of fixed cages are hapas.

- Floating cages are the most common type of fish cages. They have a net bag that is held by a buoyant collar or frame that floats on the water surface. They can be shaped and sized according to the farmers’ needs, and they can be used in a wider variety of sites.

- Submersible cages have a net collar that is supported by a frame or rigging. They can be hung from buoys or floating frames on the water surface, or they can have variable buoyancy that allows them to move up and down the water column. They can be placed to take advantage of the environmental conditions, such as bringing them up to the surface in good weather and submerging them during toxic algal blooms or extreme weather.

- Submerged cages are wooden boxes with slats or net bags that are secured to the substrate by stones or posts. They are used in flowing waters or lakes, and they are submerged below the water surface.”

Major features of fish cage

A floating fish cage usually consists of four basic components:

- Float collar system that provides buoyancy and shape to the cage. It can be made of steel or plastic pipes, wood, or bamboo.

- Netting system that encloses the fish and allows water to flow through. It can be made of fish netting, plastic mesh, or woven material.

- Sinker system that provides weight and stability to the cage. It can be made of metal, concrete, or stones.

- Mooring system that anchors the cage to the bottom or the shore. It can be made of ropes, chains, or cables.

Steps of cage construction and installation

A. Cage construction

When constructing a cage, it is essential to use materials that are water and rot-resistant, light, strong, weather-resistant, fouling-resistant, smooth, and non-abrasive for fish. Also, the materials should be draft-free and affordable.

Cut the frame materials into the desired lengths and angles, depending on the cage shape and size.

Assemble the frame materials into the cage structure, using the appropriate fasteners and Joints.

Attach the netting materials to the frame, using the appropriate tools and methods, such as staples, clips, or ropes.

Attach the feeding ring or collar (Feed Barrier) materials to the top of the cage, using the same tools and methods as the netting. This prevents floating feed from washing through the cage sides.

Attach the lid to the top of the cage, using the same tools and methods as the netting, and add the opening mechanism.

Fill the frame with buoyant materials, such as expanded polystyrene (EPS) blocks, if needed. Other examples of cage frame buoyant material include; plastic drums, HDPE pipes, and sealed Styrofoam barrels

Test the cage for buoyancy, stability, and durability, by floating it in the water and applying some pressure and weight.

B. Cage installation

Select a suitable site for the cage, considering the water depth, quality, area, and accessibility.

Mark the site with buoys or stakes, and measure the distance and direction between them.

Prepare the mooring system for the cage, which can be a single-point, a two-point, or a four-point system, depending on the water depth and current. The mooring system can consist of anchors, ropes, chains, and buoys, which can firmly secure the cage to the bottom or the shore.

Transport the cage to the site, using a boat, and lower it into the water, using a crane or a winch.

Attach the cage to the mooring system, using the appropriate tools and methods, such as shackles, swivels, or clips.

Adjust the position and depth of the cage, according to the water level and the fish species.

Stock the cage with the fish seed, using the appropriate tools and methods, such as buckets, nets, or pipes.

Note: When positioning cages on the farm, it is crucial to set them perpendicular to the current to optimize water exchange and facilitate access for feed harvesting. Furthermore, consider the natural movement routes and habitats of other aquatic animals, such as otters.

To minimize the risks of poor water quality and disease spread, maintain minimum distances between cages; For LHVD cages, this distance should be at least 2 meters between cages within the same row and 10 meters between rows. For HVLD cages, the distance depends on the cage diameter, with a recommended minimum of 30 meters apart for a 10-meter diameter cage.

Fish tanks

Tank aquaculture system refers to a method of raising aquatic organisms, such as fish or shrimp, in enclosed tanks or containers. This approach is commonly used as an alternative to traditional open-water farming methods. Tank aquaculture systems offer several advantages, including better control over environmental conditions, reduced risk of disease transmission, and the ability to optimize water quality. These systems are particularly useful when factors like temperature fluctuations, salinity variations, water availability, land constraints, or environmental regulations limit the feasibility of other aquaculture production methods.

Types of fish tanks

Aquaculture tanks are of various types, each tailored to specific requirements and preferences. These systems are primarily characterized based on their shape, function, size, material composition, and mobility. Here’s an in-depth exploration of the different types of tank aquaculture systems:

a) Rectangular tanks

b) Circular tanks

1. Shape: The shape of the tank can affect the water flow, oxygen distribution, and waste removal. Common shapes include;

- Circular Tanks: These are a popular choice in aquaculture due to their efficient use of space. They promote optimal water circulation, ensuring uniform conditions for aquatic organisms. The rounded shape minimizes stress points and facilitates ease of cleaning.

- Rectangular Tanks: Rectangular tanks are often chosen for their simplicity and suitability for space utilization. They are well-suited for grow-out purposes, providing a simple layout for efficient feeding and monitoring of fish.

- Conical Tanks: These are designed with a tapering shape, promoting efficient water flow and easy harvesting. These tanks are commonly used in hatcheries for the rearing of fish larvae or fry.

2. Function of the tank determines the type and number of fish that can be cultured in it.

- Hatchery Tanks: Specialized for the early stages of fish development, hatchery tanks provide controlled conditions for hatching eggs and nurturing larvae until they reach a suitable size for transfer into grow-out tanks.

- Grow-Out Tanks: Designed to facilitate the maturation and development of fish to market size, grow-out tanks provide optimal growth conditions required for the specific species being cultivated.

- Aquaria Tanks: These tanks are designed for display purposes in public aquariums or research institutions. They emphasize aesthetics and visibility, providing a transparent view for showcasing aquatic life.

- Holding Tanks: Used for temporary containment, holding tanks facilitate the transportation of fish or quarantine. They are essential during processes such as grading, sorting, or relocating fish within the aquaculture facility.

3. Size: can range from small troughs that hold a few gallons of water, to large tanks that can hold thousands of gallons.

- Troughs: These are small, narrow tanks often used for specialized purposes, such as the rearing of small fry or the isolation of specific individuals.

- Small, Medium, or Large Tanks: Tanks are categorized based on their capacity and intended use. Small tanks are suitable for experimental or small-scale aquaculture, while medium and large tanks cater to commercial operations with higher production volumes.

4. Construction Material

- Plastic Tanks: Lightweight and durable, plastic tanks are commonly used for their cost-effectiveness and versatility.

- Fiberglass Tanks: These offer durability and resistance to corrosion, making them ideal for long-term use. They are particularly favored in harsh aquatic environments.

- Concrete Tanks: Robust and stable, they are often employed in larger aquaculture facilities. They provide a solid structure and are capable of maintaining stable water conditions.

- Wood/Metallic Lined Tanks: They are lined with wood or metal making them ideal for aesthetics. These materials can offer additional insulation and structural support.

5. Mobility

- Fixed Tanks: These are stationary tanks permanently installed within an aquaculture facility, providing a stable environment for the continuous rearing of fish.

- Portable Tanks: Designed for flexibility and mobility, portable tanks are often used in temporary or experimental setups. They allow for relocation based on changing requirements.

Standard fish tank features

A fish tank system typically consists of the following standard features:

Inlet: The inlet is the point where water enters the fish tank from an external source, such as a tap, a pump, or a filter. The inlet design can vary depending on the type and size of the fish tank, but it should allow for adequate water flow and oxygenation. Some common inlet designs are spray bars, nozzles, or diffusers.

Outlet: The point where water exits the fish tank and returns to the external source or drains away. The outlet design can also vary depending on the type and size of the fish tank, but it should prevent clogging and overflow. Some common outlet designs are siphons and valves.

Direction of water flow: This refers to the pattern and speed of water movement within the fish tank. The direction of water flow can affect the water quality, the oxygen level, the temperature, and the behavior of the fish. The direction of water flow can be adjusted by changing the position, angle, or power of the inlet and outlet devices. Some common water flow patterns are laminar, turbulent, or circular.

Water mixing: This is the process of blending water from different sources or with different characteristics, such as temperature, pH, or hardness. Water mixing can help maintain a stable and optimal environment for the fish and prevent thermal stratification or chemical gradients. Water mixing can be achieved by using pumps.

Length, width, and depth ratios: The length, width, and depth ratios refer to the dimensions and shape of the fish tank. The length, width, and depth ratios can affect the water volume, surface area, lighting, and appearance of the fish tank. The optimal length, width, and depth ratios depend on the type and number of fish, the available space, and the personal preference of the owner.

- Drainage type/system: The drainage type/system refers to the method and frequency of removing water and waste from the fish tank. The drainage type can affect the water quality, the maintenance, and the cost of the fish tank. This can be manual or automatic, partial or complete, and continuous or intermittent. Some common drainage systems are water changes, gravel vacuums, or sumps.

Maintenance practices

After you have constructed your aquaculture production unit, you need to maintain it regularly and properly to ensure its functionality and productivity. Maintenance practices involve inspecting and monitoring your system, preventing and controlling diseases, and performing routine maintenance tasks. Depending on the type of production unit you have, such as ponds, cages, and tanks, the maintenance practices may vary. Some of the specific practices for each production unit are:

Ponds

- De-silted: This involves removing the accumulated sediments from the bottom of the pond, which can reduce the water depth, oxygen levels, and nutrient availability. De-silting can be done manually, mechanically, or biologically, depending on the size and type of the pond.

- Walls reconstructed and strengthened against erosion: This involves repairing any cracks, or holes in the pond walls, which can cause water loss, flooding, or contamination. Walls can be reinforced with materials such as stones, concrete, or sacs of sand

- Leakages repaired: Any sources of water leakage in the pond, which can affect the water balance, temperature, and salinity are identified and sealed. Leakages can be caused by faulty pipes, or valves, or by burrowing animals or plant growth. Leakages can be detected by methods such as dye tests and water level measurements.

- Clean the pond regularly by removing any debris, dead plants, or uneaten fish food from the surface or the bottom of the pond, which can decompose and release harmful substances or pathogens.

- Maintain the right water level, temperature, and chemistry through regular monitoring and adjusting the water parameters such as depth, pH, hardness, ammonia, nitrite, and nitrate, which can affect the fish health and growth.

Fish Cages

- Wash and dry the cages immediately after use to prevent the accumulation of dirt, algae, and other contaminants that can reduce the water flow and oxygen exchange in the cages. Washing and drying the cages will also prevent the corrosion and deterioration of the cage materials.

- Mend any damage in the net bag and cage frame as soon as possible. A damaged net bag can allow the fish to escape or the predators to enter, resulting in losses and reduced profits. A damaged cage frame can compromise the stability and buoyancy of the cage, making it vulnerable to strong currents or waves.

- Store the cages while hung in a net shed or similar structure to avoid damage from sunlight, rain, wind, or animals. This also protects cages from theft. The net shed should be well-ventilated and spacious enough to allow proper drying, easy access, and inspection of the cages.

- Monitor the water quality and the fish condition regularly. The water quality should be tested for parameters such as temperature, dissolved oxygen, pH, ammonia, nitrite, and turbidity. The fish condition should be checked for signs of stress, disease, or parasites. Any abnormality or problem should be addressed promptly by adjusting the feeding, aeration, or fish medication.

- Rotate the cages periodically to different locations within the water body to prevent depletion of nutrients and the accumulation of waste in one area, which can affect the water quality and fish growth. Rotating the cages will also expose the fish to different environmental conditions, such as temperature, light, and current, which can increase their adaptability and resilience.

Fish Tanks

- Keep the tank clean by removing any algae, debris, or uneaten food from the water and the walls. You can use a scrubber or an algae scraper to remove residue.

- Repair the tank as soon as leakages are noticed to prevent water loss, flooding, or oxygen deprivation. Consider using silicone sealant to fix small cracks or holes in the tank.

- Always ensure that water and air pumps and valves are in good working condition by checking them regularly and cleaning them.

- Regularly test the water parameters such as pH, Dissolved oxygen, temperature, nitrite, and nitrate at least once a week using a water testing kit. These parameters affect the fish’s health and comfort, and they should be kept within the optimal range for the reared fish species.

- Perform systematic partial or complete water exchanges every week or two, depending on the tank size and fish population. Water change reduces the accumulation of waste and toxins, and replenishes the minerals and nutrients in the water.

- Feed your fish the right amount and type of food according to their dietary requirements. Avoid overfeeding, as this can lead to poor water quality and disease. Make sure to remove any uneaten food after a few minutes of feeding.

Aquaculture is a growing and promising industry that can provide food security, income, and employment for millions of people around the world. It is essential to construct and maintain your aquaculture production units in a way that is efficient, sustainable, and adaptable. You need to perform regular maintenance and inspection of your production unit, as well as prevent and control any diseases that may arise. It is also important to keep up with the latest trends and innovations that could improve the construction and maintenance of your production unit, such as automation and renewable energy. By following these guidelines, you can ensure the success and sustainability of your aquaculture production unit, as well as the quality and quantity of your product.